Increasing Profitability in Furniture Manufacturing: A Guide to Transitioning from Manual Production to CNC

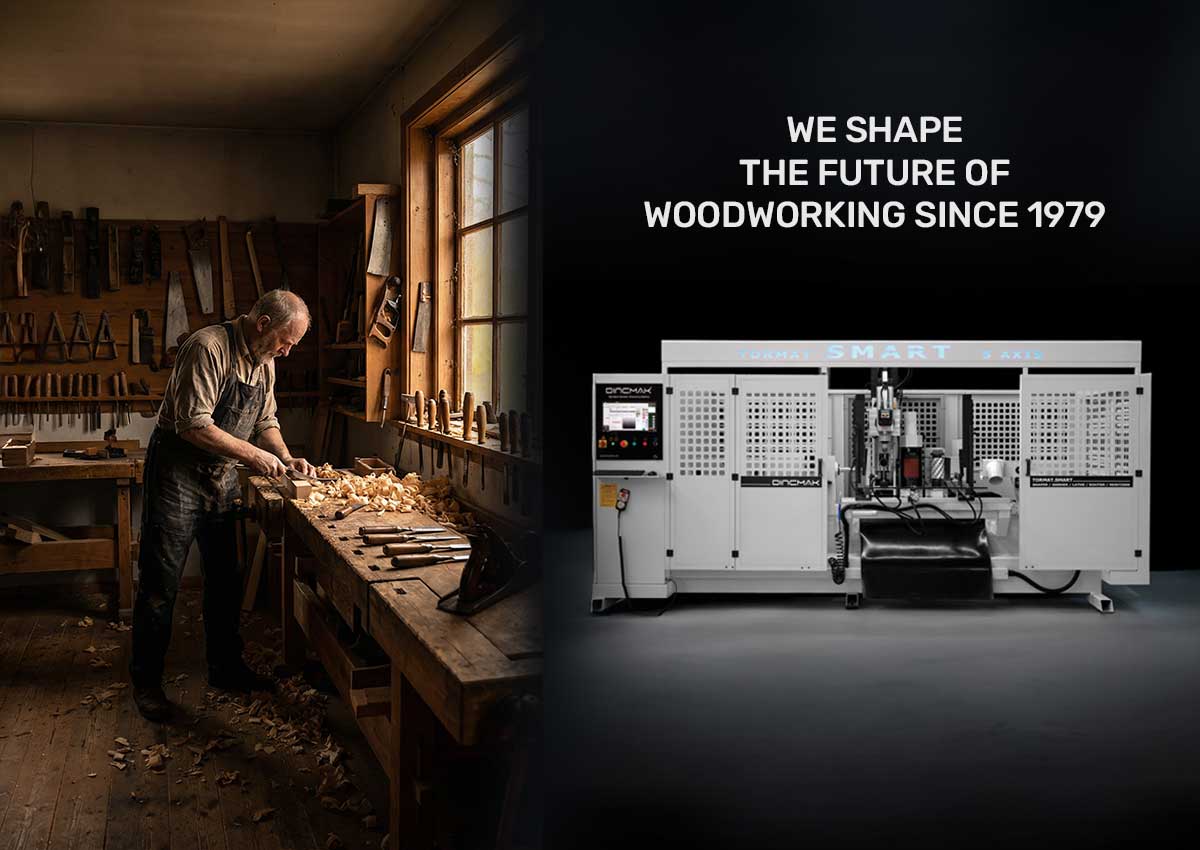

The furniture manufacturing industry is one of the most competitive production fields, where speed, quality, and cost efficiency must be perfectly balanced. Rising labor costs, increasing customer expectations, and the demand for consistent quality are pushing manufacturers to rethink traditional production methods. In this context, transitioning from manual production to CNC-based manufacturing is not just a technological upgrade—it is a strategic move that directly increases profitability.

The Limitations of Manual Production

Traditional furniture manufacturing relies heavily on craftsmanship and experience. While this approach has undeniable value, it presents several limitations as production volume increases:

- Production speed depends heavily on operator skill

- Inconsistent dimensions and quality between parts

- Higher error and scrap rates

- Time loss in producing complex geometries

- Difficulty in maintaining sustainable serial production

These factors increase unit costs, extend delivery times, and weaken competitive advantage.

What Is CNC Technology and What Does It Offer?

CNC (Computer Numerical Control) machines perform manufacturing operations with high precision under computer control. In furniture production, CNC technology enables:

- Drilling operations

- Contour cutting

- Grooving and slotting

- 3D and complex form machining

All of these processes can be completed on a single machine with exceptional repeatability and accuracy.

How CNC Improves Profitability

One of the strongest advantages of transitioning to CNC manufacturing is the rapid return on investment. This is driven by several key factors:

- Reduced Scrap and Error Rates

CNC machines produce each part with identical dimensions and quality. Incorrect cuts, measurement errors, and rework requirements are significantly reduced. - Significant Increase in Production Speed

Operations that take hours manually can often be completed in minutes using CNC technology. This dramatically increases daily and monthly production capacity. - Optimized Labor Costs

CNC systems reduce dependency on highly specialized manual labor. Fewer operators can manage production more efficiently and consistently. - Standardization and Serial Production Advantages

Producing the same product repeatedly with the same quality is a major advantage, especially for project-based and mass furniture manufacturing. - High Value-Added Product Capabilities

Complex designs that are difficult or impossible to achieve with manual methods can be produced easily with CNC. This enables manufacturers to offer higher-margin, premium products.

Key Considerations When Transitioning to CNC

Investing in CNC technology is not only about purchasing a machine. Proper planning is essential for success:

- Selecting a machine that matches production capacity

- Correctly determining the need for 4-, 5-, or 6-axis systems

- Ensuring software and G-code infrastructure are suitable for production

- Availability of technical service and spare parts

- Operator training and ease of use

A Strong Transition with Dinçmak

At Dinçmak, we developed the OPTIMUS 6-Axis CNC Machining Center to ensure a smooth and efficient transition from manual to CNC production for furniture manufacturers.

- High precision and repeatability

- Superior performance in complex geometries

- Powerful software infrastructure tailored for woodworking

- Advantages of local manufacturing and fast technical support

OPTIMUS is not just a machine—it is an investment that elevates your entire production philosophy.

Conclusion

Manual production represents the foundation of craftsmanship, but in today’s competitive market, CNC technology is no longer optional—it is essential. Transitioning from manual production to CNC manufacturing reduces costs, increases capacity, and significantly improves profitability.

With the right machine, the right technology, and the right partner, CNC investment becomes the key to sustainable success in furniture manufacturing.

Dinçmak is your trusted partner in moving your production into the future.

Dinçmak Blog